There are many different ways to print self-adhesive labels & stickers. This guide gives an overview of the most popular production methods. If you want to learn more about how custom stickers & labels get printed, keep on reading.

Digital vs. traditional

The industry splits printers (also known as presses) into two main categories; digital and traditional.

Digital printers use print-heads to apply multiple colored inks, or toners, to a substrate (printable media) in one go. These presses usually print CMYK (cyan, yellow, magenta & black (key)). Sometimes this is increased to include white, orange, violet, green, and others, so it's possible to print more colors.

Traditional printers tend to use printing screens or plates to apply a single spot color at a time. They are remarkably fast to print but expensive to set up compared to digital presses because of the overhead to make a plate or screen.

Cut singles, sheets, or rolls

Stickers & labels get printed onto sheets or long rolls (known as a web). Depending on the type of label you want will depend on the type of printer needed.

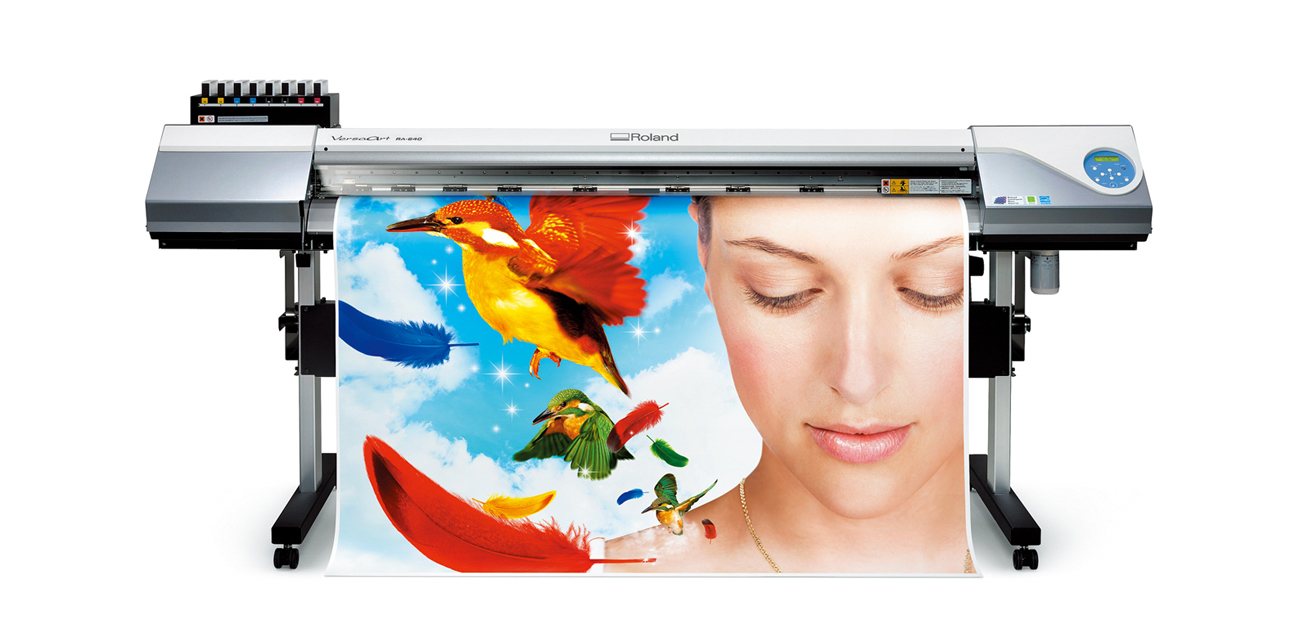

Here's an example of an industrial, narrow web, roll-to-roll printer:

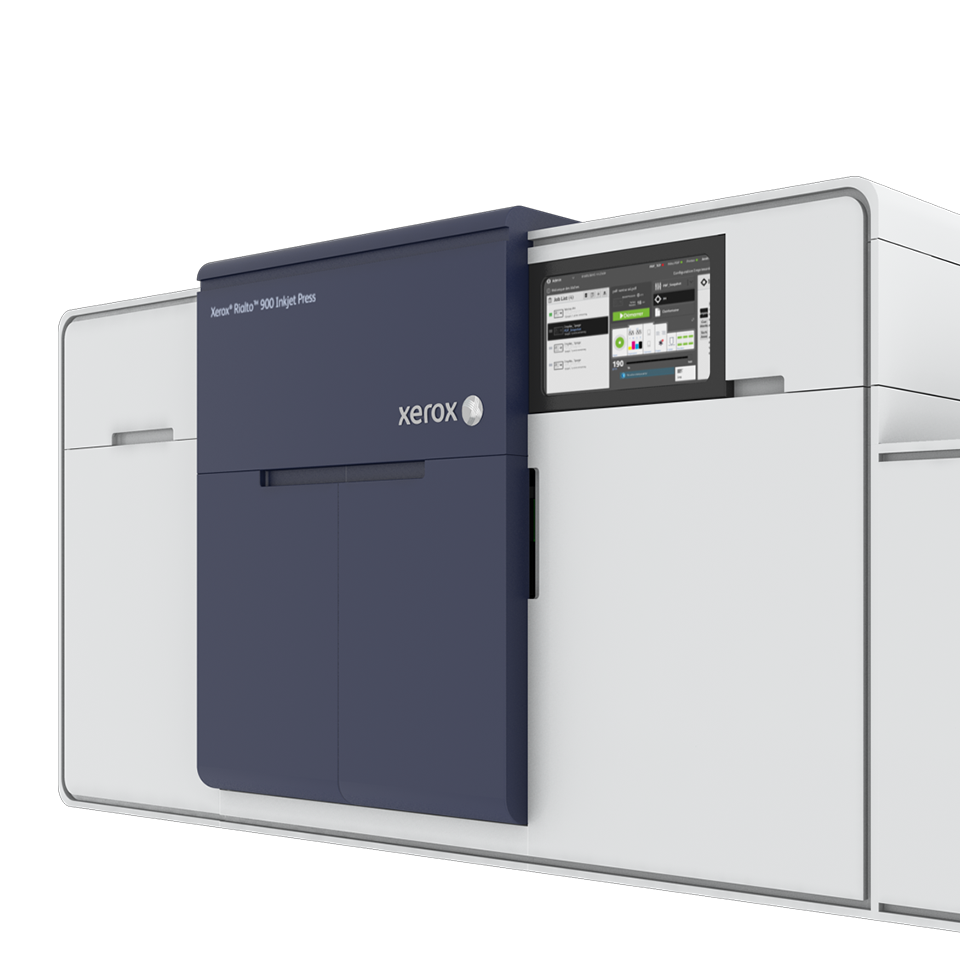

And this is what a sheetfed printer looks like:

You can also get wide-format printers that are typically for printing vehicle wraps. These can print up to widths of 3m.

Different types of digital printing

Here are some of the most used digital printing technologies:

- Inkjet. It's the most popular, especially in wide format printing. Ink can be solvent or water-based, or cured by UV.

- Dry toner. Used by companies like Xeikon, they print with dry powers & cure them instantly using UV light.

- Digital offset. Using a unique 'ElectroInk' developed by HP, the ink gets applied to a rubber 'blanket' before being applied to the web in a single 'hit.' This gives the ink time to wet out, resulting in an excellent result.

- Thermal transfer. Ink gets printed on media through heat & pressure. A roll of ink on a PET carrier (a transparent plastic film), usually made from a wax & resin mix, is melted by a print head. The ink gets transferred to the media, creating the image.

Different types of traditional printing

Here are some of the most widely used traditional printing methods:

- Offset. A plate gets chemically treated, so ink only sticks to the wanted areas. The 'picture' gets transferred to a blanket then applied to the paper or plastic media. This process gets repeated for all colors to build a complete image.

- Screen printing. Ink gets transferred onto a substrate by being pushed through a mesh using a rubber squeegee. The mesh has a blocking stencil applied, so the ink gets transferred in the desired shape. This process gets repeated for all colors to build a complete image, usually from CMYK colors.

- Flexo. A flexible plate, wrapped around a roller, applies the ink directly to the plastic or paper media. Modern printers are super-fast, printing up to 750m per minute.

Comments

0 comments

Please sign in to leave a comment.