This article contains the most common problems to look out for when receiving your new batch of stickers or labels.

We've been printing custom stickers & labels since 2006 and have made our fair share of mistakes. Over time we've developed processes & machines to avoid these problems.

We've created this guide, so you know what to look out for.

Dirt under the laminate

If your stickers are laminated, watch out for tiny pieces of dust under the laminate layer. They can look like a small grain of sand or dirt or even be as large as a piece of hair!

If you see these, you'll know your print supplier has a dirty environment and ensure you get replacements sent.

Banding in the print

Inaccurate calibration can cause a digital printer to print banded. The result are lines through your print where it should be a solid color. Like this:

Mis-registered cutting

There are many ways to cut stickers, and some are more accurate than others. One of the most important things is to ensure the cut is exact around the edge of the sticker.

If it's not near perfect, borders can look uneven and ruin the effect of your label. To avoid misregistered cutting ruining your design, minimize borders close to the edge.

Too much ink

Some digital printers are susceptible to this problem - especially with orange & red inks.

Too much ink on the media causes an orange peel effect that impacts the appearance of the color.

There is no way to stop this; you need to use a print supplier who has the latest technology and maintains their machines properly.

The wrong colors

Not getting the exact color is a problem. Two factors often cause this:

- Giving the wrong color values in artwork

- The printer cannot print the required color

When giving artwork to your printer, be sure to convert colors to CMYK and provide a Pantone reference or a physical sample for them to match.

To avoid the 2nd point, choose a color that can be printed in CMYK. If not, suppliers will need to make spot colors for you or print in CMYKOVG.

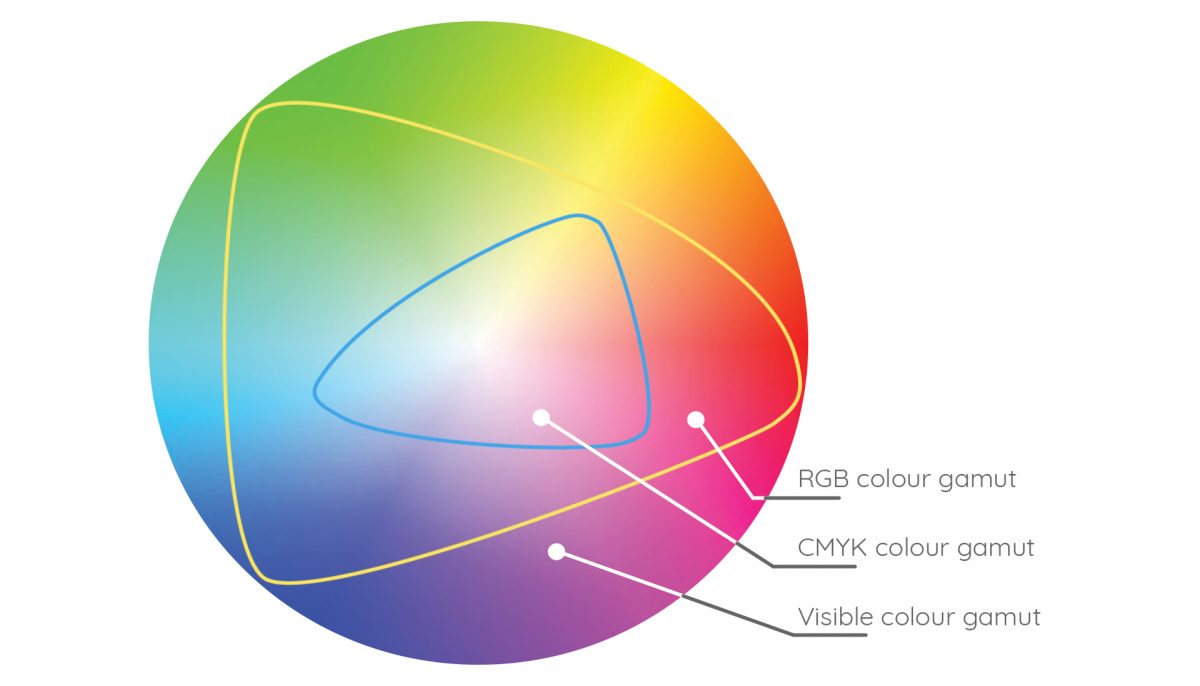

This image shows the difference in colors we can see versus an RBG & CMYK color spectrum.

Delamination

Delamination can happen when the transparent plastic film applied to the sticker to protect it starts to separate from the printed media.

Delamination occurs for two main reasons:

- Not using the correct laminate. The glue isn't strong enough, so it starts to peel.

- Not degassing properly. Solvent inkjet printers need time for their ink to cure before laminating so the ink can gas off before being trapped beneath the laminate. This process can take 24-hours, and some print suppliers may not leave this time.

Curling

Curling of your sticker will happen when the tension of the laminated layer is different from the printed layer. One layer pulls the other & they curl.

Labels can also curl because cheap backing paper can take on moisture, causing the paper to expand and curl.

Hard to peel your sticker

When trying to peel your sticker & the backing is tearing, it's cut too deep, so the backing paper tears. It's frustrating and happens because the cutter settings are incorrect and apply too much pressure or energy, so they cut to deep.

Comments

0 comments

Please sign in to leave a comment.