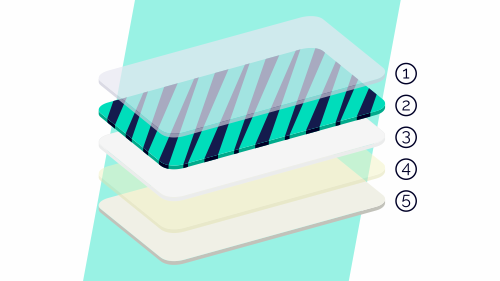

A sticker has five layers. Starting from the top, they are:

- Laminate; (optional) for maximum protection.

- Ink; your printed design, usually printed in CMYK colors.

- Media; the paper or plastic we print your design on.

- Adhesive; keeps your label stuck down - very important!

- Backing paper; often forgotten but very important. Protects your sticker and makes it easy to peel & apply.

Here is a little more information about each layer of a sticker:

Laminate

This layer is optional. Use an over-laminate for outdoor or long-term applications where the added durability is required. For example;

- Laptop and phone stickers

- Branded giveaways

- Water bottle labels

- Stickers on bikes

- Bumper stickers

- Industrial equipment stickers on tractors, wheelbarrows, or similar

- Stickers for premium applications, such as branded merch.

You can get liquid laminates, where you only need a little protection. However, the most popular laminates are thin, transparent plastic films that are either gloss or matte. These give the maximum protection. A good rule is thicker = more durable.

Ink

There are many ways to print stickers. Traditional & digital are the 2 main categories.

Our focus in this section is digital.

Digital printing is growing exponentially because of advances in printing. If you're buying less than 5000 stickers, digitally printing them makes sense because the setup costs are much lower than traditional printing.

However, that is changing as digital printers get faster & higher resolution. Today some digital printers can match the speed of traditional printers.

Digital printers typically print in CMYK. CMYK stands for; Cyan, Magenta, Yellow, and Black (key). Some more advanced digital print machines can also print white. In the last few years, printers have added orange, violet, and green inks to widen their color gamut. Meaning, they can print a broader range of colors.

At Sticker it, we have digital printing machines with up to 8 ink stations, meaning we can hit a broad range of colors and print white in one go.

Media

The media is the plastic or paper layer we print on; this can come in various types and even more colors.

The most popular types of media are; plastic and paper.

Both types of media are available in a wide range of colors, such as; white, clear, metallic silver & gold, neon, and many more.

Adhesive

There are three main types of adhesive; removable, permanent, or high-tack.

Removable grade adhesive is only suitable for short-term applications. It's for uses where you want to remove the sticker - for example, removable paper packaging labels and sealing envelopes.

Permanent adhesive is the most popular. It's the best all-rounder and is what we recommend in 95% of applications. It can stick to; metal, glass, plastic, paper, and more.

The high-tack adhesive is suitable for hard to stick to surfaces, such as rubber or low-energy plastics - for example, water buckets, wheelie bins & dirt bikes.

Backing paper

Backing paper (aka release liner) is often forgotten. The purpose of the paper backing is to make the sticker or label easy to peel. Nearly all backing papers are good enough to do this effectively.

A thick backing can also ensure you have a premium feel to your sticker or label.

If you're applying stickers in-house, to your product, for example, don't worry about the backing paper. It can be thin because no customer will see it.

If you're giving handouts or selling stickers to your customers, choose a thick backing paper to give your stickers a premium feel. It also makes your stickers easier to peel, which is a good bonus.

Comments

0 comments

Please sign in to leave a comment.